unleashing the power

10sec. challenge

We Listen

We listen to your story and ask essential questions to find out to understand the goals of concrete workers.

We Think Along

We use our experience and expertise to design and produce top-quality power trowels that are ideal for concrete professionals worldwide.

Design & Technique

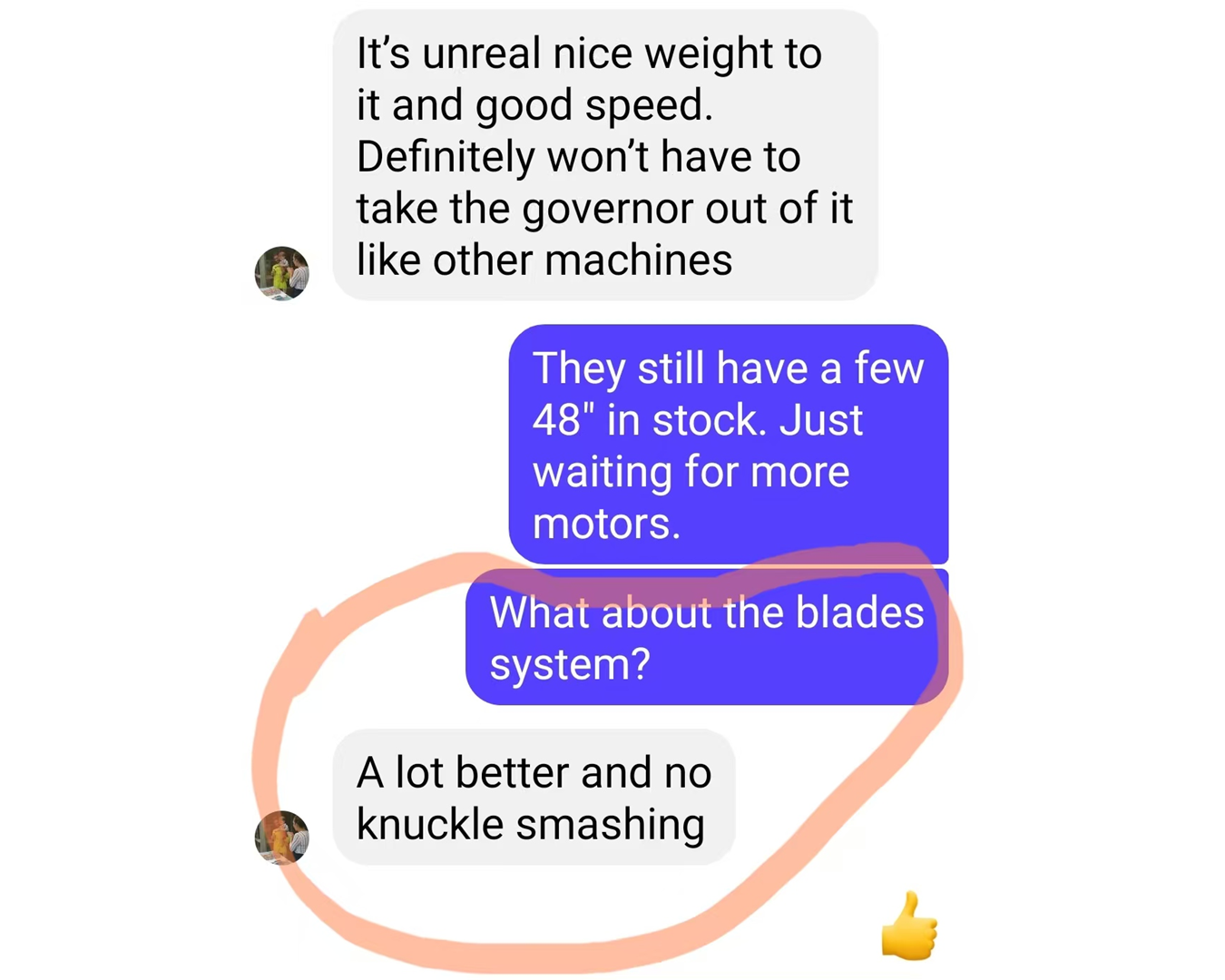

Our innovative quick blade-changing system complies with, and surpasses, international safety operating standards.

How the best in the business operate. No shortcuts. No compromise. 🏆

Elite results demand elite tools. The COHEN CONCRETE crew + Full-Track Power = Perfection at elevation.

Tag a contractor who needs to see this. 👇

🔗 For the equipment that builds legacies, see our bio.

#ConstructionReels #ConcreteFinishing #CrewLove #FullTrack #PowerTrowels #CohenConcrete #HowItsDone #ConstructionLife

This season, don’t just work hard — own the grind! 💪

Tired of gear that holds you back?

Upgrade to equipment that saves time, boosts productivity, and makes every pour smoother.

Introducing Full-Track Power Trowels — engineered by concreters, for concreters. Trusted on sites across Australia, these machines help you finish faster and work smarter.

✅ Professional-grade & field-proven

✅ Maximise efficiency & reduce fatigue

✅ Built tough for Aussie conditions

Ready to work like a pro?

👉 Explore our range & read real reviews:

www.fulltrackglobal.com

www.full-track.com.au

Need help choosing? Drop us a question below! We’ll help you find the right machine to power through your busiest season.

Upgrade to Full-Track — the tools the pros trust. ⚙️

#FullTrack #PowerTrowel #ConcreteEquipment #ConstructionTools #ConcreteLife #ContractorTools #TimeSavingTools #JobSiteUpgrade #AustralianMade #ConcreteContractor #Efficiency #BuiltToLast #ConcretePros #ToolsOfTheTrade

@highlight

Cohen Concrete Inc & Full-Track 🤝

Down in Fort Myers, the heat is intense and the humidity is higher—but the standards stay top-tier. To deliver high-quality slabs consistently under the Florida sun, the team at Cohen Concrete relies on the precision and durability of Full-Track Power Trowels.

Whether they are working on a massive commercial foundation in Lee County or a precision industrial floor, this partnership ensures:

✅ Faster finishing times to beat the SWFL sun.

✅ Superior floor flatness for every project.

✅ Maximum operator comfort and reliability on the toughest jobsites.

We’re honored to support the Cohen team as they continue to build Fort Myers and the surrounding areas with the best equipment in the game!

🌐 Learn more about our equipment here:

US & Global: www.fulltrackglobal.com

Australia: www.full-track.com.au

#FortMyersConstruction #SWFLBuilders #LeeCounty #ConcreteFinishing #PowerTrowel #FullTrack #CohenConcrete #FloridaConcrete #flatwork

@followers

🔥 Mastering concrete in the Melbourne heat! 🔥

Watch Samuel Shields (aka the Concrete Karate Kid 🥋) lay down a flawless finish with nothing but pure focus… and the iconic Aussie “safety thongs”! 👣

This is peak performance in concrete finishing. Precision, power, and skill all in one.

The right gear makes it possible. Samuel uses industry-leading equipment from Full-Track.

👉 Explore their global range: www.fulltrackglobal.com

👉 For Aussie expertise:

www.full-track.com.au

What’s the one piece of gear you can’t work without? Drop it below! 👇

#Concrete #ConcreteFinishing #PowerTrowel #ConcreteLife #Construction #MelbourneTradie #TradieLife #Flooring #FullTrack #ConcreteEquipment #ConcreteArt #ConstructionAustralia #ConcreteTok #InstaConstruction #DemoDays #FlipFlops

Guess who’s back? 2026 is shaping up beautifully. Keep an eye on us— unbelievable, amazing things are on the way. 💪💪💪🔥🔥🔥🌎🌎

A new year means new projects, new deadlines, new finishes.

Thank you for choosing Full-Track Power Trowels—for trusting our equipment when the surface has to be perfect.

In 2026, we remain your partner in precision, your support in reliability, and your resource for performance. Let’s build something remarkable.

Happy New Year from Full-Track Power Trowels.

As we look back on 2025, our gratitude runs deep.

A massive thank you to the hard-working contractors and crews who trust our machines day in and day out. Your skill turns concrete into art.

And a standing ovation 🎬 for our outstanding distributors network! Your 2025 effort was nothing short of heroic:

You are the true backbone of this journey.

If 2025 was about building momentum, we can`t wait to see what 2026 unveils. 🎁 The next chapter is going to be something special.

Wishing you and yours a holiday season full of warmth, well-earned rest, and celebration. 🎅🤶

Cheers to the future,

The Full-Track Power Trowel Team

P.S. Get ready. 2026 is looking smooth. 😎 #PowerTrowelFamily #BuiltWithDistributors #Concrete2025 #ThankYouPartners #ConstructionLife HereForThePour 2026Ready

7 days ‘til Christmas, What’s on your Christmas wish list? A new tool, or just a nap after lunch?

#ConcreteContractor #PowerTrowel #ChristmasWish #ChrissyLunch #AussieChristmas #ToolHumor

A LITTLE YEAR-END GIFT TO YOURSELF? 🎁✨

You work hard. It`s time your equipment works harder.

Meet the FULL-TRACK POWER TROWEL — the undisputed power trowel of concrete finishing. The mightiest in the world, built for those who demand nothing less than absolute dominance on the job site.

Why it’s the ultimate upgrade:

⚡ REVOLUTIONARY FAST BLADE CHANGE — Swap blades in under a minute. Yes, really.

⚡ UNMATCHED DURABILITY — Engineered for the toughest pours and longest days.

⚡ EFFORTLESS TRANSPORT — Grab the matching heavy-duty trolley/dolly with OFF-ROAD TIRES and move it anywhere, smoothly.

Stop waiting. Start finishing stronger, faster, and smarter.

DM us to order or call/text 239-229-7081 (USA) to get yours before the year ends!

🔗 Explore more in our bio or visit:

🌐 www.fulltrackworldwide.com

🌐 www.full-track.com.au

#FullTrack #PowerTrowel #ConcreteFinishing #ContractorGift #ConcreteTools #ConstructionLife #FinishStrong #YearEndSale #JobSiteReady #HeavyEquipment #ConcreteContractor #BuiltToLast #ConstructionTech #BladeChange #Productivity #OffRoad #ConcretePour #BuyOnceCryOnce #TreatYourself

#Followers

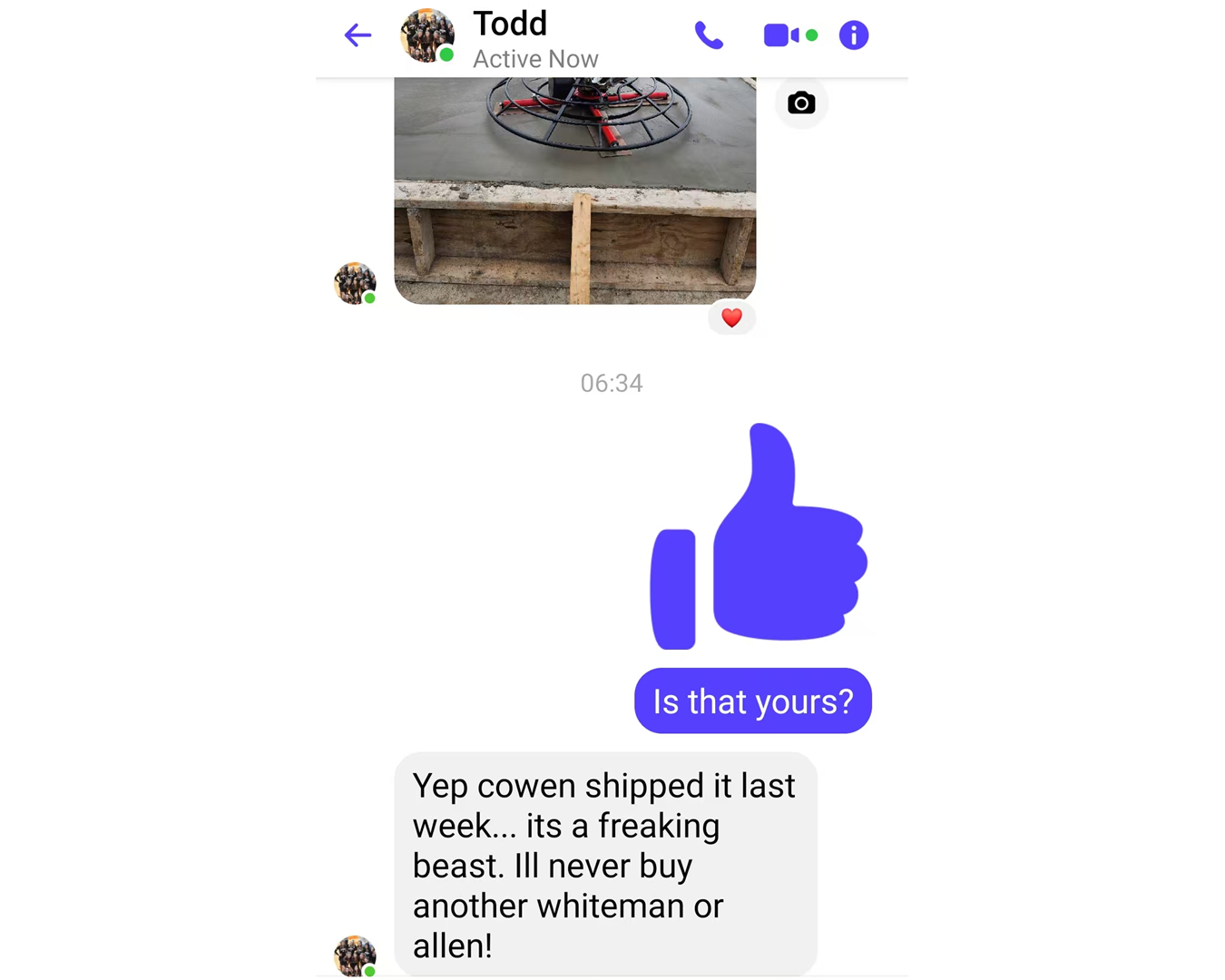

From crate to perfect slab 🏗️➡️✨ Swipe to see the full journey of a Full-Track power trowel! We don`t just deliver a machine, we deliver a flawless finish.

See it in action and experience the difference. Link in our bio to explore models and pricing!

🔗 www.fulltrackworldwide.com

🔗 www.full-track.com.au

#FullTrack #PowerTrowel #ConcreteFinish #ConcreteLife #Construction #ToolsOfTheTrade #AustralianMade #BuyLocal #ContractorLife #ConcreteArt #SatisfyingConstruction #BeforeYouBuy

Check out these Full-Track power trowels, expertly fitted with custom upgrades by Rick Staats at DownUnder Service and Repairs! ✨

This isn`t just an upgrade; it`s an investment in your finish.

✅ Custom Water Spray Kits: Achieve a perfectly controlled, consistent finish every time.

✅ Brilliant LED Light Kits: Extend your workday and enhance safety after dark.

✅ Expert Installation: Get peace of mind with professional workmanship from a trusted team.

Huge shoutout to Rick Staats and the crew at DownUnder Service and Repairs for their fantastic work! 👏

For the world`s best power trowels, check out:

🌐 www.fulltrackworldwide.com

🌐 www.full-track.com.au

Tag a concreter who needs to see this! 👇

@followers

#EfficiencyUpgrade #ConcreteSolutions #PowerTrowel #ConcreteBusiness #DownUnderServiceAndRepairs #BuiltNotBought #FullTrack #FullTrackWorldwide

Full-Track wishing all the hardworking concrete pros and their families a safe, restful, and happy Thanksgiving! What are you thankful for this year?

www.fulltrackworldwide.com

www.full-track.com.au

@followers @highlight

#FullTrackPowerTrowel #ConcreteLife #Thanksgiving #Grateful #Construction #PowerTrowel #FinishedOnTime #TurkeyTime

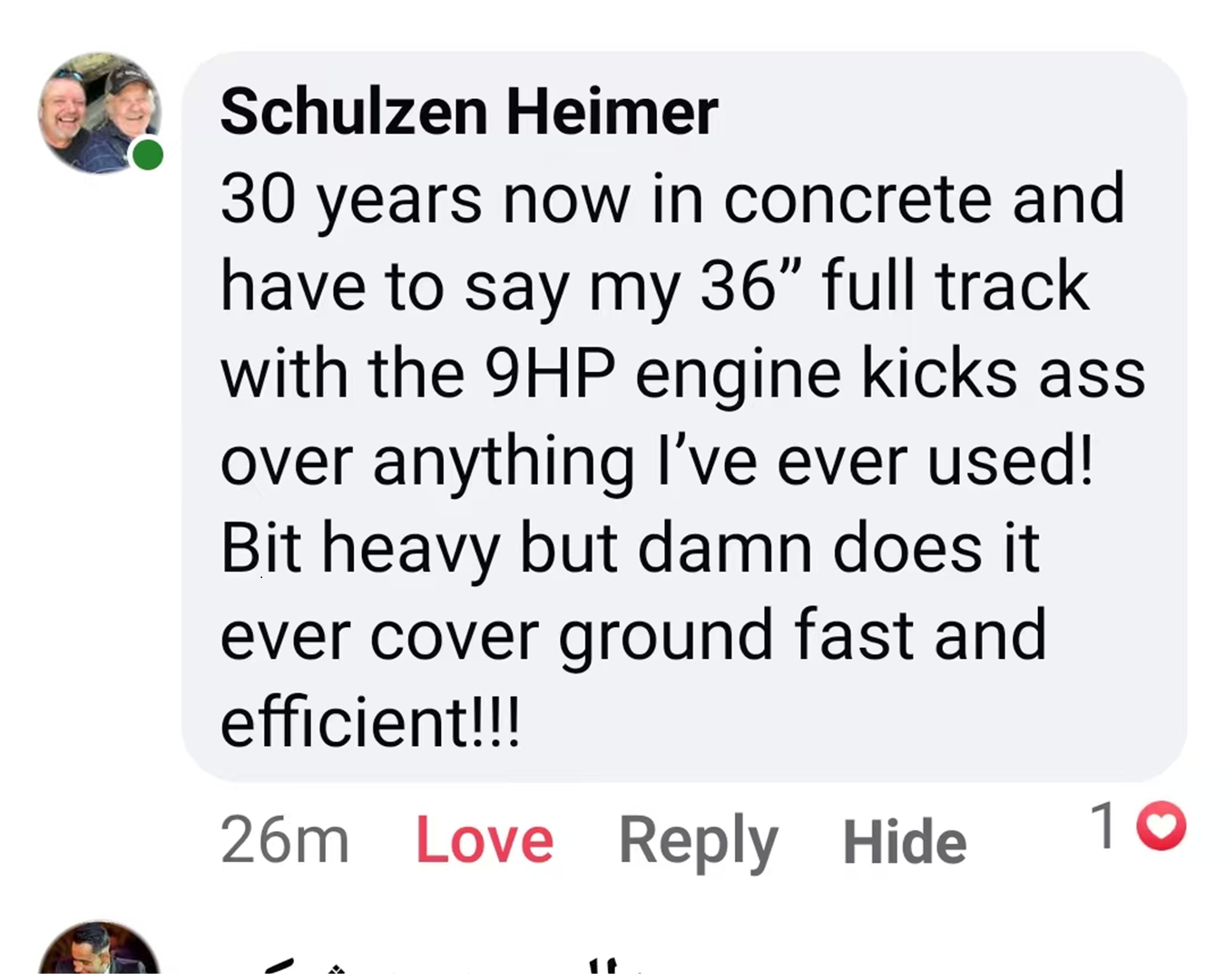

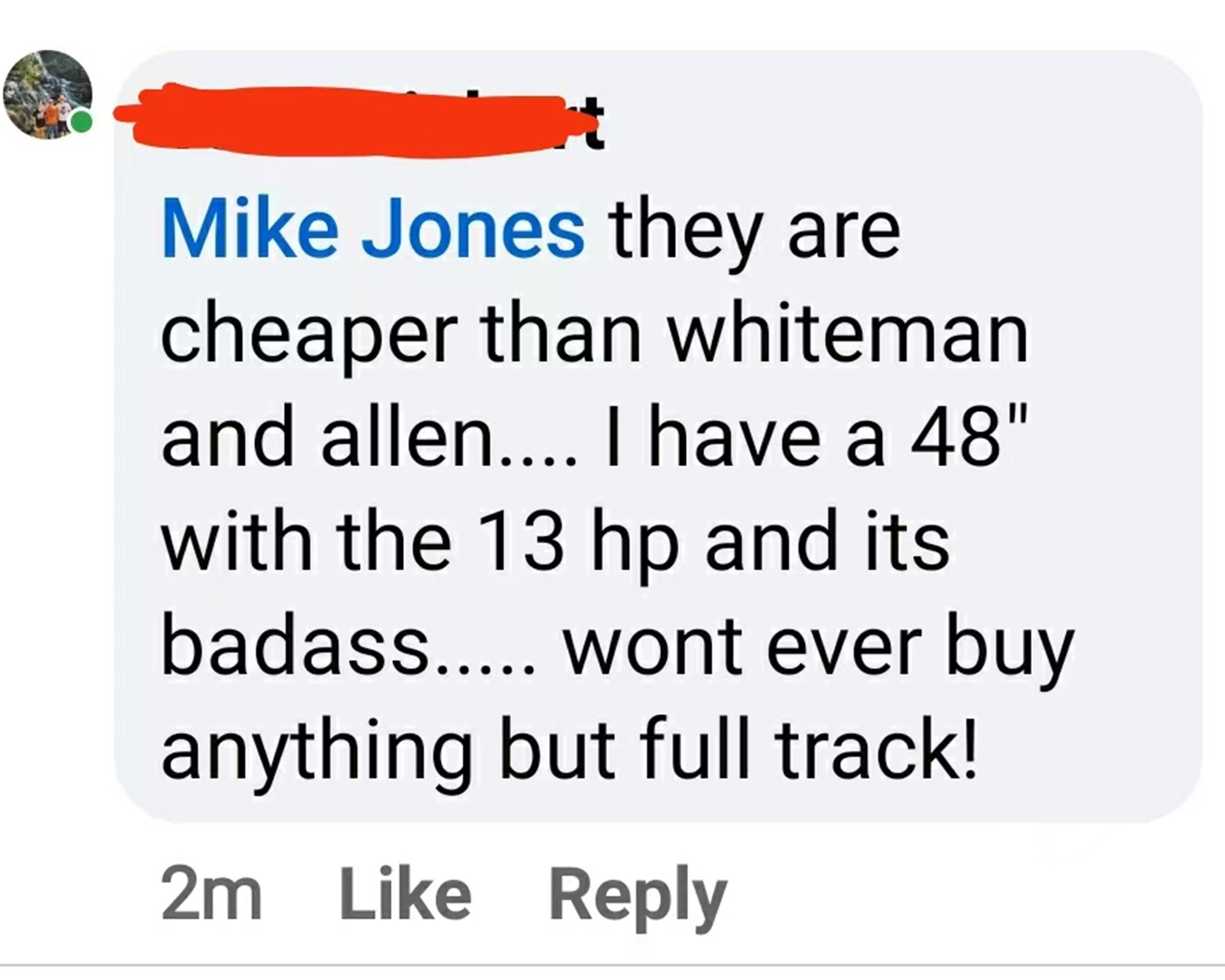

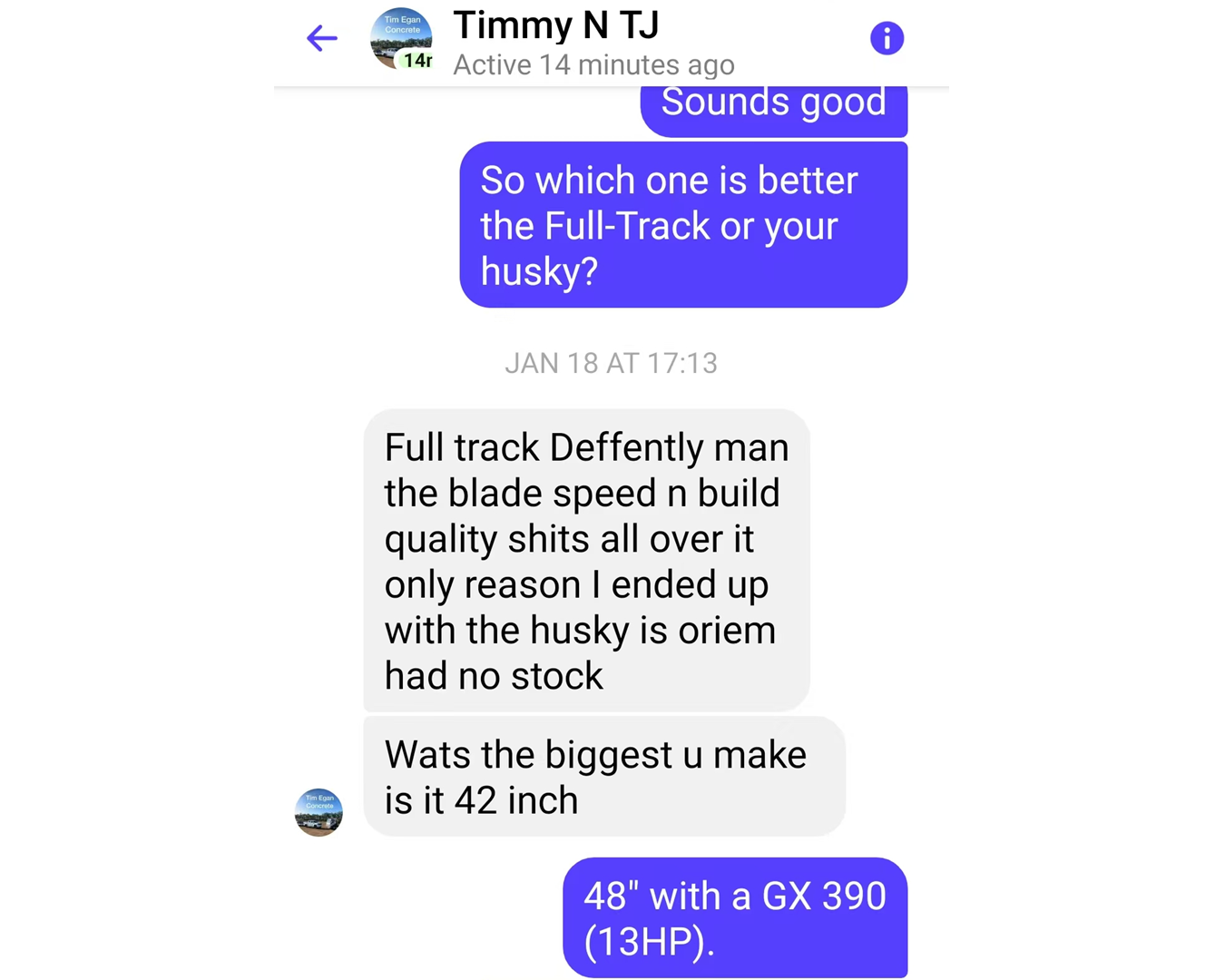

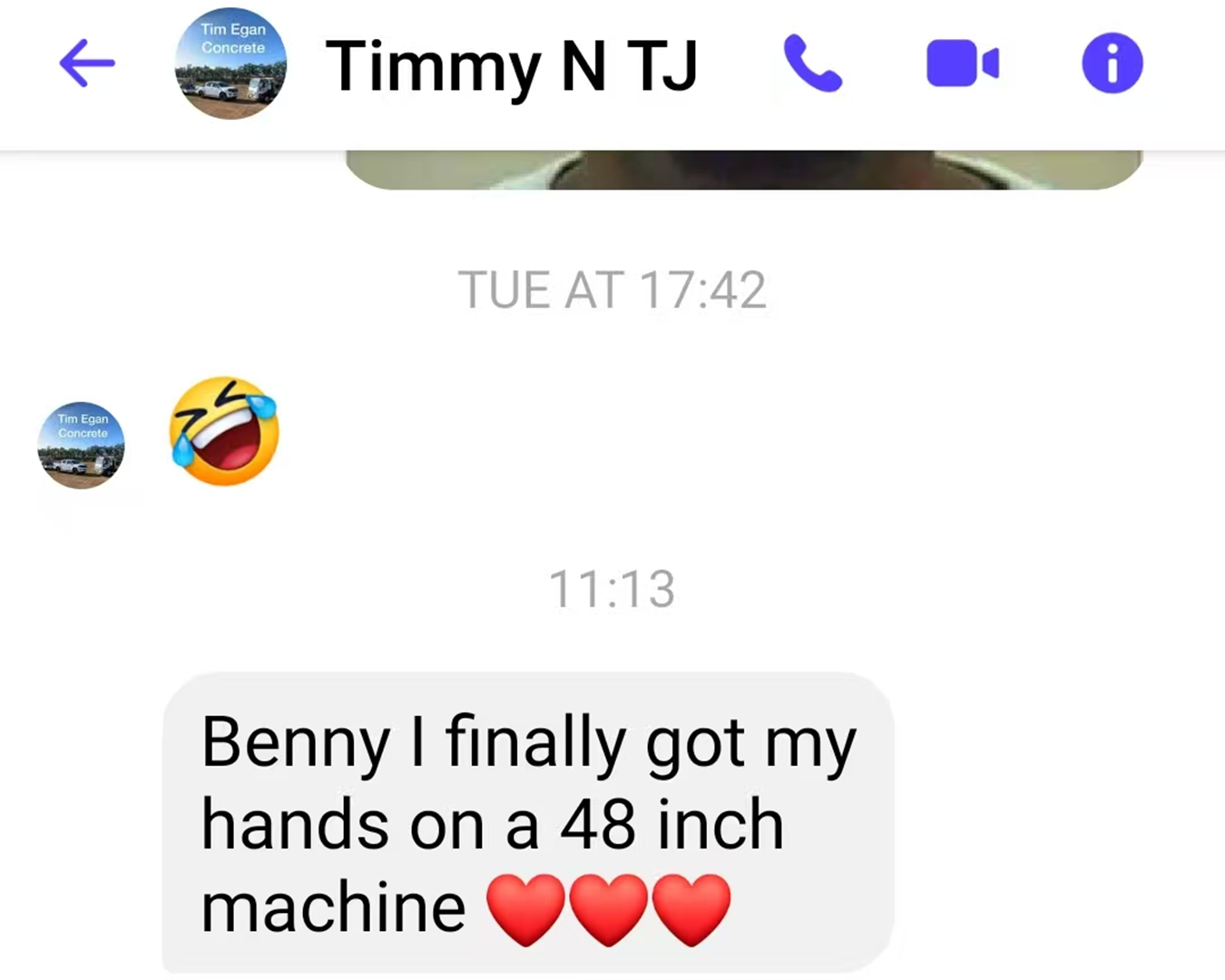

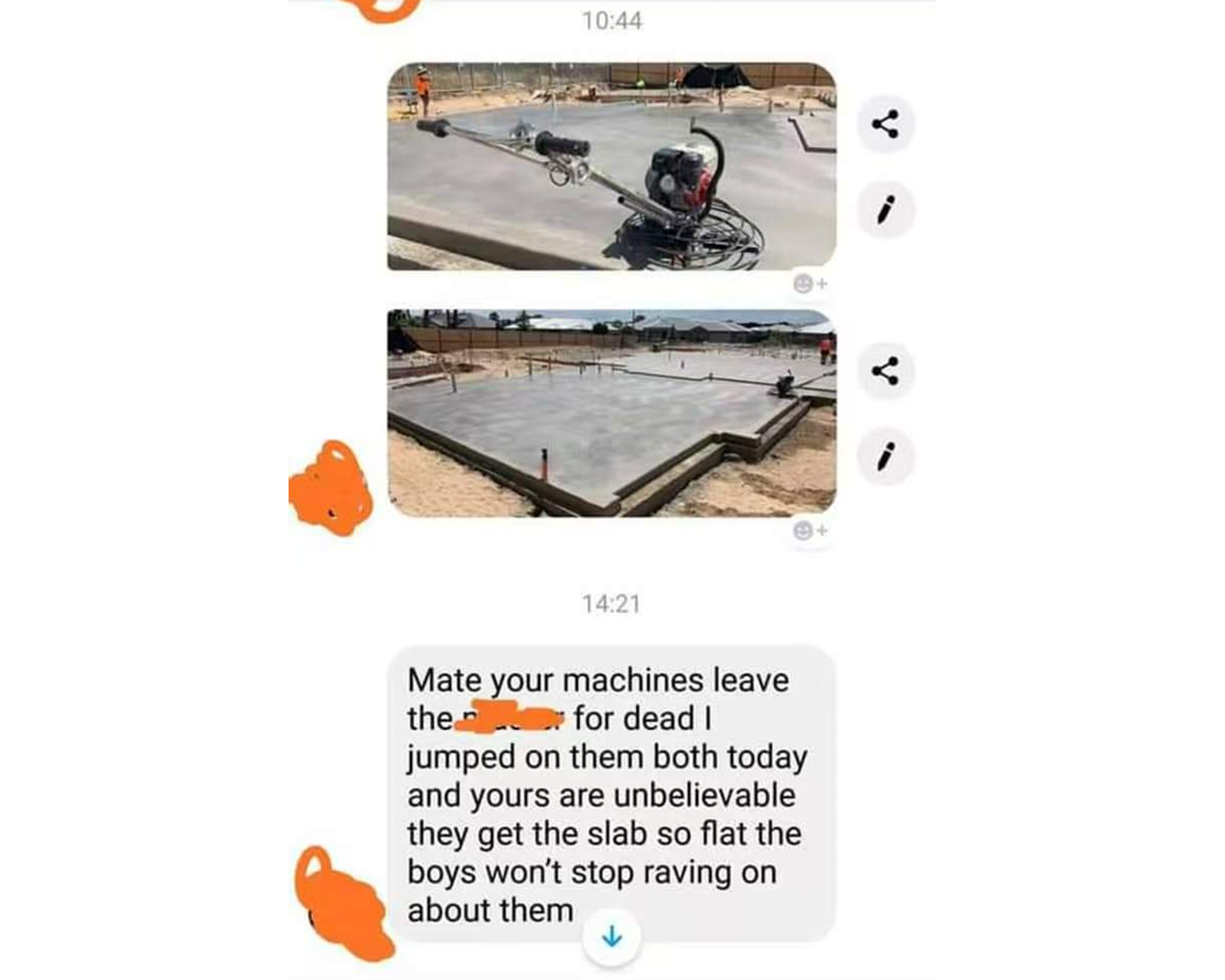

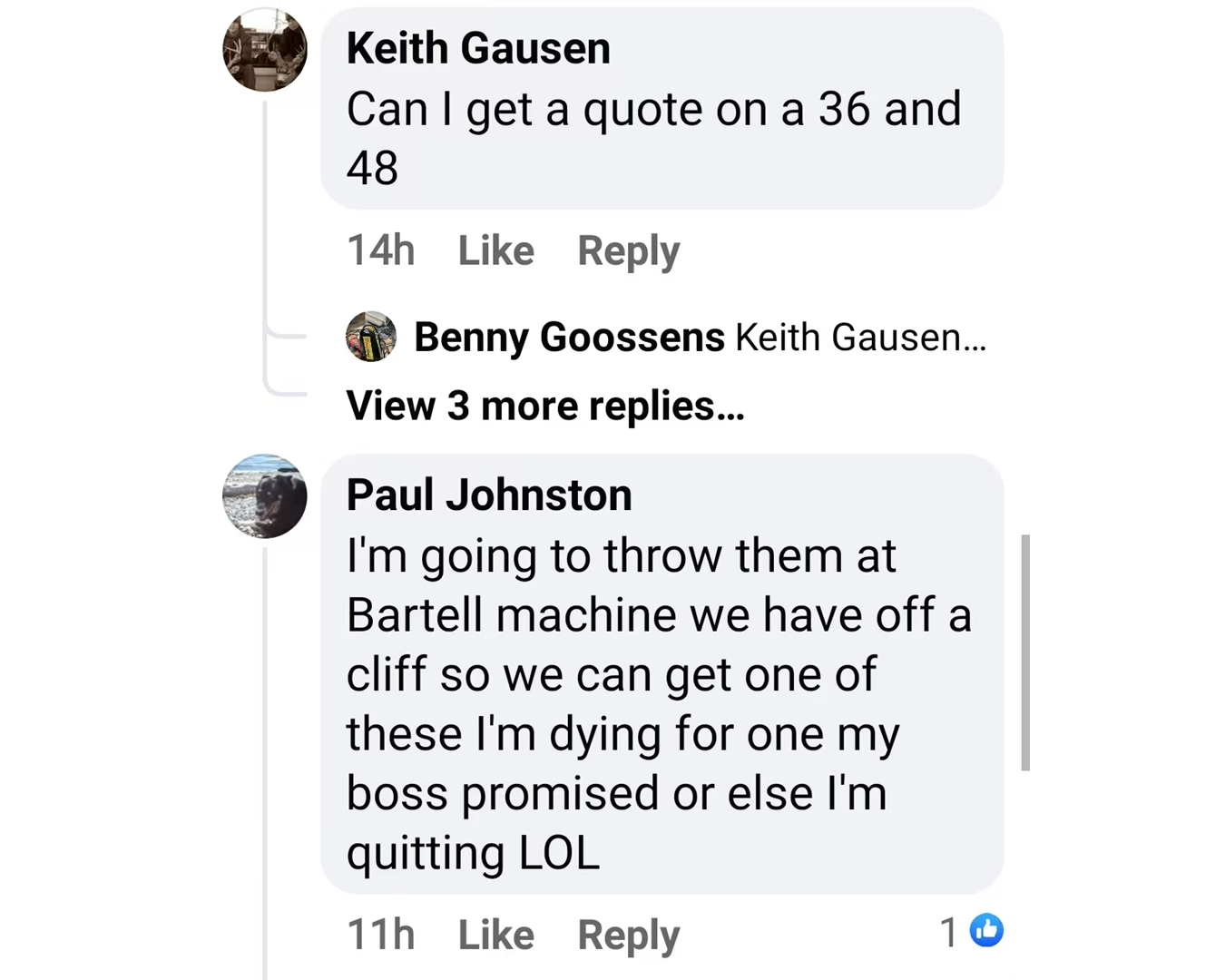

"Our Clients' Testimonials."

EASIER| FASTER| SAFER

The FT-432 Power Trowel, is a versatile and efficient Trowel designed for precision troweling in smaller areas, confined spaces, or around extrusions. This innovative Power Trowel harnesses all the power and performance of our renowned 36" Series Power Trowels to surpass the capabilities of other edging walkers on the market.

Crafted with precision and designed for optimal performance, the FT-432 Power Trowel is the perfect companion for projects that demand accuracy and efficiency. Whether you are working in tight spaces or intricate corners, this Trowel is engineered and designed to deliver superior results.

Experience the difference with the FT-432 Power Trowel and elevate your troweling capabilities to new heights. Trust in our commitment to quality and innovation as we deliver a product that exceeds expectations and sets a new standard in the industry.

The "Pro FT-436" is equipped with a heavy-duty variable-speed torque converter clutch in place of the standard clutch. The "Pro FT-436" is a “36” little Beast” walk-behind trowel”, which provides contractors with a much wider range of rotor speeds and torque.

36" Dollies/Trolleys

Complement your Full-Track power trowel with our sturdy 36" Dollies/Trolleys, designed for transporting your 36" Full-Track trowel effortlessly around your job site.

Our FT-448 comes standard with a 9HP class Honda Motor/Engine and lifting hook. These trowels are built for the most demanding job sites.

The Pro FT-448 Walk-Behind Trowel comes equipped with a 13HP Class Honda Motor/Engine. The Heavy-Duty variable torque converter clutch allows for low-speed torque and high-speed finishing. This heavy-duty, high-speed “48” Animal” Walk-Behind can tackle the most demanding of projects.

48" Dollies/Trolleys

Complement your Full-Track power trowel with our sturdy 48" Dollies/Trolleys, designed for transporting your 48" Full-Track trowel effortlessly around your job site.

CLUTCHES

- FULL-TRACK machines are standard equipped with a Variable Speed clutch on the motor and on the gearbox.

- These links ensure that both a very low and high RPM can be created without strength loss.

- FULL-TRACK machines are adjusted to 200 rpm.

- This speed results in quicker finishing of floors, which saves the entrepreneur time and money.

HONDA MOTORS

- FULL-TRACK only uses Genuine Honda motors.

- Proven reliability.

- Guaranteed more power.

- Quieter performance.

- Lower fuel consumption.

- Reduced emissions.

- PS: Other brands of Motors can be used.

GEARBOX

- FULL-TRACK Gearbox Casts are manufactured from High–Quality Aluminium.

- The layering has been calculated on all possible strengths and frictions and therefore early wear is avoided.

- Internal damage breakdown services can be carried out with minimum disruption to operations.

- The remuneration costs will diminish strongly because of this.

HANDLE

- FULL-TRACK machines are standard equipped with a trap–less handle at altitude.

- Both taller & smaller concreters can work unforced because of this.

- The handle is made out of stainless steel and is completely maintenance-FREE for life.

- Handles are equipped with a SRPC-System (Solid Rod Pitch Control).

- NO SNAPPING CABLES.

SPIDER & ARMS

- A FULL-TRACK Arm is almost the same length as the Blades, so therefore declines have been minimized and the trowel area continues to be preserved.

- All arms will pitch Simultaneously which results in small disparities being removed and the flatness of the floor being increased.

- Arms stuck inside the spider are avoided by using HIGH QUALITY BRONZE BUSHINGS and therefore subject to minimum maintenance and easy to replace.

- Super cost-effectively.

Our Commitment to our Customers

This is what we do

01

Performance

– Unrivaled Concrete Finishing

– Guaranteed Efficiency and Durability

– Superior Full-Track Design

02

Satisfaction

– Tailored Customer Support Services

– Dedicated to Client Needs

– Full-Track Expert Assistance

03

Innovation

– Leading Technological Advancements

– Full-Track’s Cutting-Edge Solutions

– Full-Track’s Commitment To Innovation

04

Sustainability

– Full-Track’s Friendly Equipment

– Concrete Finishing Solutions

– Efficient Full-Track Power Trowels